In Process Piping, one important area that engineers and piping designers must understand the concept of “flange classes.” These classes help engineers to choose the right flange without going through calculations based on the design pressure and temperatures. ASME and ASTM specify all the Selection guidelines. In this post, I will try to explain the significance of ASME classes.

Classes are not only designed to select the right flange but also help plant operators and fitters to select the right replacement spool with flange. As an example, If the plant has an ASME-built tank with pre-built CL150 flanges as the nozzle on multiple locations, the Welder and fitter can use the same class Weld-Neck, Slip on, or other based on the situation. Note: all CL150 flange for same NPS have Samilat bolt hole pattern and Hole diameter.

Flange Class Fundamental Parameters

1. Pressure Rating (Class):

The pressure rating or class of a flange means how much maximum pressure it can withstand in PSI per Square inch. As an example, the Class 150 flange can withstand 150 psi pressure per square inch. It doesn’t mean that the whole flange is designed for a total of 150 psi. The actual Maximum allowable working pressure directly depends on the temperature of the fluid and material of a flange. See table below. Most Common pressure classes are 150, 300, 600, 900, 1500, and 2500. To understand the pressure class.

Note: CL300 flange doesn’t mean it is rated for 300psi. Please see the temperature & pressure rating based on flange materials at the end of the table.

2. Temperature Rating:

Flanges are also designed by ASME to operate within specific temperature ranges. Flanges are made with different materials and manufacturing methods like forging, casting or cutting from a plate. Both material and construction methods directly impact the MAWP of a particular flange. ASME and ASTM have set out rules for flange manufacturers to follow. ASME also defines the relation between pressure-temperature rating and construction material for each flange to help engineers and designers choose the right flange. I hope it makes sense.

The temperature rating is expressed in degrees Fahrenheit. Different materials and construction methods may have varying temperature limits. Careful consideration of the operating temperatures is vital to ensure the flange can withstand the conditions to which it will be exposed.

How to Apply it For Process Piping:

When it comes to designing or selecting flanges for a piping system, engineers must carefully assess the operating conditions.

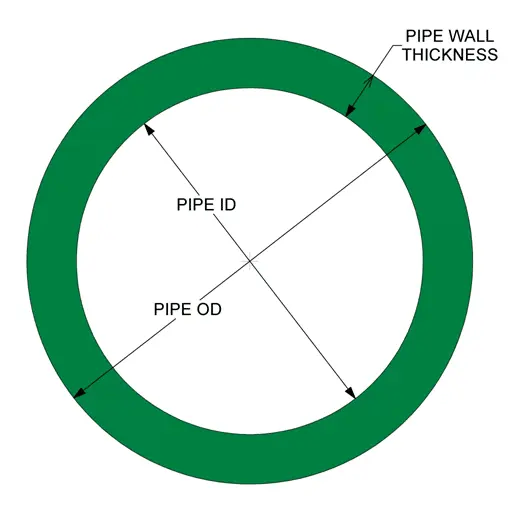

To put this into real example, A Class 150 flange may be suitable for lower-pressure sections of the system, while a Class 600 flange would be deployed in areas where higher pressures are anticipated. Matching the flange class with the corresponding pressure and temperature requirements is a fundamental step in designing and constructing a reliable piping network. Flange NPS size, Design Pressure, and temperature are 3 fundamental factors in choosing the right flange.

Frequently Asked Questions (Q&A)

Q: Does “Class 300” mean the flange is rated for 300 psi?

A: No. This is the most common mistake. A Class 300 flange (made of Carbon Steel) is actually rated for roughly 740 psi at ambient temperature (100°F). The “Class” refers to a category in the ASME B16.5 tables, not a direct pressure limit.

Q: Why does the pressure rating drop as the temperature goes up?

A: As metal gets hotter, its molecular structure softens, reducing its yield strength. To maintain a safe margin of safety and prevent the flange from deforming or “leaking” under pressure, the allowable working pressure is legally required to be lowered.

Q: Can I bolt a Class 150 flange to a Class 300 flange?

A: No. Even if they are the same pipe size (e.g., both 4 inches), they are not physically compatible. A Class 300 flange is thicker, has a larger bolt circle, and often uses more or larger bolts than a Class 150 flange.

Q: Is there a difference between “Class,” “Pound (#),” and “Lb”?

A: In the field, these terms are used interchangeably. “300 Class,” “300#,” and “300 Lb” all refer to the same pressure-temperature rating group.

Q: How do I know which material group to use?

A: Flange ratings are divided into Material Groups (e.g., Group 1.1 for Carbon Steel, Group 2.2 for 316 Stainless Steel). You must find the specific table in the ASME B16.5 standard that matches your flange’s material to get the correct pressure/temperature limits.

Q: When should I move from a Class 150 to a Class 300 flange?

A: You should upgrade when your system’s maximum operating pressure exceeds the Class 150 limit at your operating temperature. For example, if you are running at 400 psi at 100°F, a Class 150 flange (rated for 285 psi) is unsafe, and you must use at least a Class 300 flange.