Understanding API 5L Pipe:

API 5L, or American Petroleum Institute Specification 5L, is a critical standard in the oil and gas industry that plays a pivotal role in the transportation of hydrocarbons. This specification sets the bar for line pipes used to convey oil, natural gas, and other fluids over vast distances. With a focus on material quality, manufacturing processes, and performance standards, API 5L ensures the reliability and safety of these pipelines.

At its core, API 5L classifies line pipes into various grades, each with distinct characteristics. The most common grade, API 5L Grade B, is widely used for general applications. However, more demanding situations call for higher-strength materials like API 5L X42, X52, X60, X65, and X70, each capable of withstanding different levels of stress and pressure.

API 5L-compliant pipes undergo rigorous testing, including non-destructive inspection and mechanical testing, to confirm their integrity. This helps prevent leaks, ruptures, and environmental disasters in the oil and gas industry.

PSL 1 vs PSL 2:

PSL 1, the more basic of the two, emphasizes fundamental requirements. It ensures that line pipes comply with the necessary chemical composition and exhibit acceptable mechanical properties. While PSL 1 specifies maximum limits for elements like carbon, manganese, phosphorus, and sulfur, it does not necessitate specific minimum values, leaving a certain degree of flexibility in the steel’s composition. Additionally, PSL 1 mandates non-destructive testing, such as hydrostatic testing, to uncover any defects in the pipes.

On the other hand, PSL 2 raises the bar considerably. It introduces stringent criteria, demanding not only maximum limits but also specific minimum values for chemical elements. This level often includes additional elements like vanadium, titanium, and zirconium, optimizing the steel for higher performance. Moreover, PSL 2 places greater emphasis on mechanical properties, requiring elevated levels of tensile strength, yield strength, and impact toughness, especially at lower temperatures. To ensure enhanced quality, PSL 2 mandates more extensive non-destructive testing methods, such as ultrasonic testing, radiographic inspection, and magnetic particle inspection.

Furthermore, PSL 2 accounts for “sour service” requirements, crucial in environments containing hydrogen sulfide (H2S). PSL 2-certified pipes offer enhanced resistance to the corrosive effects of H2S, ensuring the pipeline’s safety and longevity.

Frequently Asked Questions (Q&A)

1. What is API 5L and why is it important?

Answer: API 5L is a specification set by the American Petroleum Institute for line pipes used to transport oil, gas, and water. It is critical because it ensures the safety and reliability of pipelines by setting strict standards for material quality, manufacturing, and performance.

2. What is the primary difference between PSL 1 and PSL 2?

Answer: PSL 1 provides a basic quality level with standard mechanical and chemical requirements. PSL 2 is a higher-tier standard with stricter chemical limits, mandatory toughness testing, and more rigorous non-destructive inspection.

3. What is “Sour Service,” and which level covers it?

Answer: “Sour service” refers to environments containing Hydrogen Sulfide (H2S), which is highly corrosive. PSL 2 pipes are specifically designed to resist the corrosive effects (like cracking) caused by H2S, making them necessary for these hazardous environments.

In summary, the choice between PSL 1 and PSL 2 depends on the specific needs of a project. PSL 1, with its basic requirements, may suffice for less demanding applications. However, PSL 2, with its higher quality standards and enhanced characteristics, is the preferred choice for projects where stringent performance and safety standards are paramount.

This is how it should be Written When you order or add description to your Drawings:

EX: Pipe, 30 NPS, SAW, SCH STD, API 5L, PSL-1, X42N

Pipe Manufacturing Methods & Abbreviations:

Pipe manufacturing methods vary depending on the material, size, and intended use of the pipes. Here are some common methods for manufacturing pipes:

Heat Treatment and Its Importance

Heat treatment processes such as normalizing, quenching, and tempering are often applied to API 5L pipes to achieve the desired mechanical properties. Normalizing refines the grain structure and improves toughness, while quenching and tempering enhance strength and resistance to cracking. For PSL 2 pipes, controlled heat treatment is especially important to meet stringent performance requirements.

Corrosion Resistance and Sour Service

In pipelines exposed to corrosive environments, material selection becomes critical. API 5L PSL 2 pipes intended for sour service must meet additional requirements to resist hydrogen-induced cracking and sulfide stress corrosion cracking caused by H₂S. These pipes undergo specialized testing to confirm their suitability for aggressive service conditions, ensuring long-term operational safety.

Typical Applications of API 5L Pipes

API 5L pipes are widely used in:

- Onshore and offshore oil and gas pipelines

- Crude oil transmission lines

- Natural gas distribution networks

- Petrochemical and refinery piping systems

- Water and slurry transportation

Their versatility and proven performance make them a preferred choice across multiple industries.

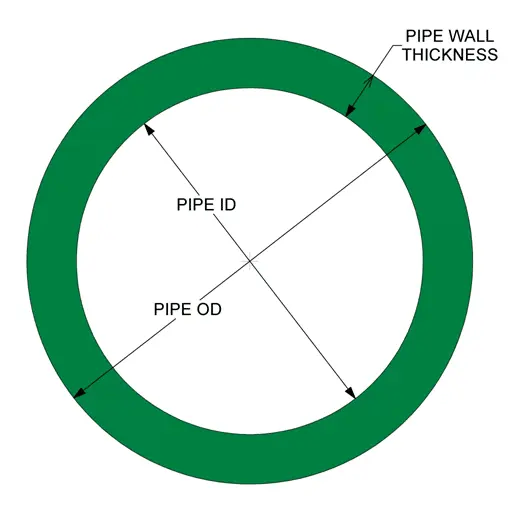

Ordering and Documentation Requirements

When ordering API 5L pipes, it is essential to clearly specify details such as pipe size, wall thickness, manufacturing method, grade, PSL level, and inspection requirements. Clear documentation helps avoid misunderstandings during procurement, manufacturing, and installation. Proper marking and traceability ensure compliance with project and regulatory standards.