It stands for American Society of Mechanical Engineers!!!

ASME is non-profit Professional association that develops and maintain codes and standards for pressure vessels to enhance public safety, and productivity of engineers. ASME is best known for improving the safety of equipment used in manufacturing and construction, particularly boilers and pressure vessels.

ASME standards are also sometimes referred to as Boiler & Pressure vessel Code or BPVC, But in reality BPVC is a small part of ASME standards. ASME covers more than that. These codes and standards are developed to regulate:

- Design Standards

- Material Specification

- Operation and maintenance of pressure vessels/process piping

- Fabrication Guidelines

- Inspection guidelines and procedures

- Non-destructive test procedures and guidelines

Sometimes, it is confusing due to the wording “Boiler & Pressure vessel Code or BPVC”. People think it only applies to boilers or high-pressure vessels or steam engines, but that is not true.

In most states within the U.S.A, any tanks that contain the pressure of more than 15 PSI must be legally designed, manufactured, and maintain in accordance with ASME rules and guidelines. It also applies to process piping.

History of ASME

Founded in 1880 by a small group of leading industrialists to provide a setting for mechanical engineers to discuss the concerns brought by the rise of industrialization. ASME has grown through the decades to include more than 125,000 members in 150 countries. Today ASME has more than 600 standards and codes available.

Steam was the driver of lots of technology in the early 19th century. Due to the nature of steam, equipment that relied on it needs constant attention and maintenance. Despite all efforts, there are multiple boiler explosions throughout the 19th century. An explosion in a shoe factory in Massachusetts, on March 10, 1905 resulted in 58 deaths and 117 injuries, which draws the attention of the whole nation and proves the need for developing boiler laws.

In 1911, ASME formed a committee to write code that resulted in the “Boiler & Pressure vessel Code or BPVC” in 1915. Later it was actually incorporated into laws for most US states.

Difference between ASME Standard and ASME Code

An ASME standard can be defined as a set of technical definitions, instructions, and guidelines. It is like an instruction manual for designers, fabricators, and operators of the equipment.

When those standards are adopted by government bodies or business contracts and enforced by law, they become a code.

Why ASME is Important

For two very simple but important Words “Safety” and “Quality“

ASME codes are written and maintained by highly qualified engineers and designers around the world. Their standards are developed to ensure the safety and quality of equipment throughout the full product life-cycle. When customer purchase ASME-certified equipment or works with ASME Certified company, It gives certainty of design and safety of operation.

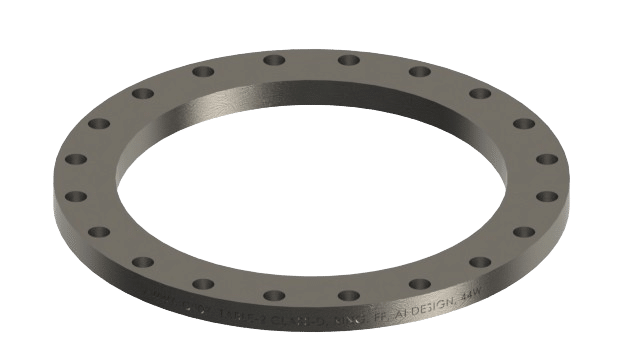

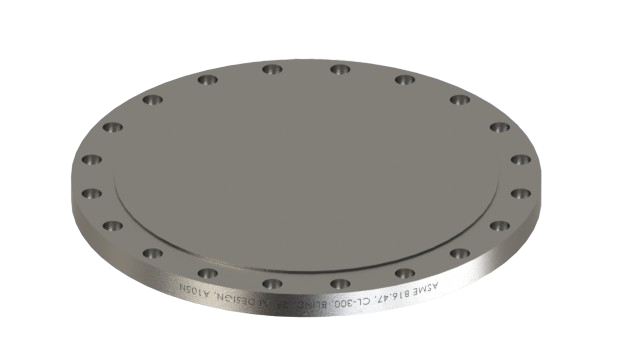

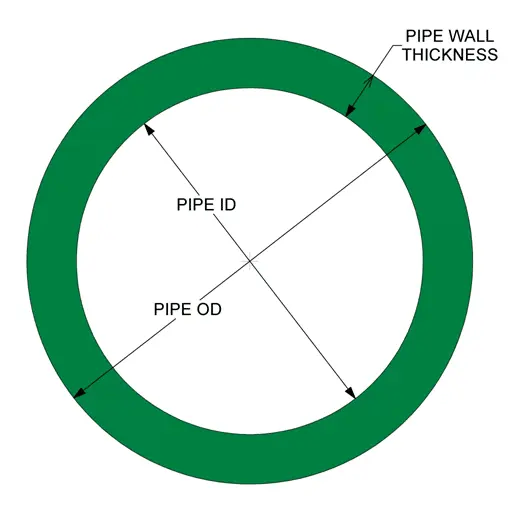

Further, ASME also governs and regulate sizes and material specification for piping and boiler fittings for universal fit and interchangeability. As an example, If you have a Vessel manufactured in Canada with an ASME B16.5 Slip-On flange nozzle, a Weld-neck Flange with a similar specification will fit perfectly with that.

List of Piping Standards, Codes and Substandard

As I have mentioned earlier, ASME have have more than 600 standards and codes. Here I have listed frequently used Standards and Sub-standards that apply to piping for your understanding:

1. ASME Code For Pressure Piping, B31

- B31.1 – Power Piping

- B31.3 – Process Piping

- B31.4 – Pipeline Transportation System for Liquids and Slurry

- B31.5 – Refrigeration Piping and Heat Transfer

- B31.8 – Gas Transmission and Distribution Piping Systems

- B31.8S – Managing System Integrity of Gas Pipeline

- B31.9 – Building Services Piping

- B31.12 – Hydrogen Piping and Pipelines

2. Standardization of Valves, Flanges, Fittings, and Gaskets, B16

- B16.1 – Gray Iron Pipe Flanges and Flanged Fittings: Classes 25, 125, and 250

- B16.3 – Malleable Iron Threaded Fittings: Classes 150 and 300

- B16.4 – Gray Iron Threaded Fittings: Classes 125 and 250

- B16.5 – Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24, Metric/Inch Standard

- B16.9 – Factory-Made Wrought Buttwelding Fittings

- B16.10 – Face-to-Face and End-to-End Dimensions of Valves

- B16.11 – Forged Fittings, Socket-Welding and Threaded

- B16.12 – Cast Iron Threaded Drainage Fittings

- B16.20 – Metallic Gaskets for Pipe Flanges

- B16.21 – Nonmetallic Flat Gaskets for Pipe Flanges

- B16.24 – Cast Copper Alloy Pipe Flanges, Flanged Fittings, and Valves

- B16.25 – Buttwelding Ends

- B16.34 – Valves Flanged, Threaded, and Welding End

- B16.36 – Orifice Flanges

- B16.39 – Malleable Iron Threaded Pipe Unions: Classes 150, 250, and 300

- B16.42 – Ductile Iron Pipe Flanges and Flanged Fittings: Classes 150 and 300

- B16.47 – Large Diameter Steel Flanges: NPS 26 through NPS 60, Metric/Inch Standard

- B16.48 – Line Blanks

- B16.49 – Factory-Made, Wrought Steel, Buttwelding Induction Bends for Transportation and Distribution Systems

3. Engineering Product Definition and Related Documentation Practices, Y14

- Y14.1 – Drawing Sheet Size and Format

- Y14.2 – Line Conventions and Lettering

- Y14.3 – Orthographic and Pictorial Views

- Y14.5 – Dimensioning and Tolerancing

- Y14.24 – Types and Applications of Engineering Drawings

- Y14.35 – Revision of Engineering Drawings and Associated Documents

- Y14.100 – Engineering Drawing Practices

Reference(s): www.asme.org