3D SCANNING SERVICES

Reverse Engineering, Design and As build Component Replacement

Our professionals and partners all over North America can provide you with various scanning applications, reverse engineering, and professional fabrication drawing for piping, and industrial designs.

Why choose Ai Designs for Piping Scans?

Quick Turnaround time for final output

submillimeter Precision for single scan

Experienced Piping designers with ASME & API Knowledge

All Inclusive and Clear Pricing Plans

How 3D scanning can help your organization?

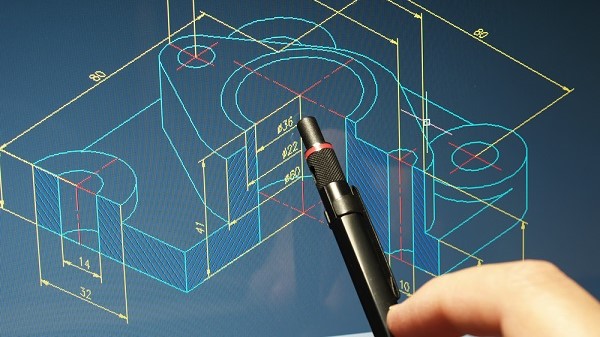

3D scanning has the ability to accurately capture everything that is seen in any particular location, including structural steel, ducting, Piping, and even small stuff like lights and handrails. It provides engineers a “digital twin” to refer to. Within this digital plant, they can look around, take measurements, and even create 3D models and 2D drawings that can be used to support specific projects. The resulting CAD drawings and models created from 3D scans will put your engineers’ minds at ease knowing that they are working with current information and they can design with confidence.

Using digital 3D scan information as an as-built reference, engineers can design complicated retrofits and upgrades that fit with existing equipment the first time, avoiding costly and usually inevitable engineering errors or miscalculations. For example, you can route new piping and duct around existing structural steel with very high precision, down to 1/4″ for highly precise design work. This helps the actual installation to go smoother and faster, resulting in less delays and downtime.

THIS IS HOW WE BRIDGE THE PHYSICAL AND DIGITAL WORLD VIA 3D SCANNING

1. Identify the Scope of work

Our team will try to gather as much information as possible like plant photographs, area of concentration, old drawings, and define the final deliverable. We also notify the plant if any special requirements like extra lights or scaffolding.

2. Capture Series of Scans

Our partner scanner will lase scan a 360º sweep of all nearby equipment in single or multiple shots based on the situation. Some of our 3D scanners are capable of taking measurements accurate to 1/4″ from a distance of 100 meters or more. The single scan could have sub-millimeter accuracy.

3. Generate Mesh/Point cloud Data

By merging multiple scans and sections of the plant, We could capture a single mine in 1 to 2 days. If required, We can align scan data with plant coordinates. After aligning all scans, we generate 3D Mesh/Cloud data. At this stage you can measure anything you like virtually and create walkthroughs if needed.

4. Convert to CAD

Not all design software can handle the STL or Point cloud data. If you would like to change the existing design/plant, Perform Inspections or make a fabrication drawing, we need to convert this mesh data into a gematrical entity and solid cad model as needed. This is the most time-consuming step where you need accuracy and expertise